http://current.com/1fff64c

August 26th, 2009

A Way to Harvest Electricity from Trees

One freezing day in February 2006, physicist Andreas Mershin

huddled with others around a tree on the Massachusetts Institute

of Technology campus to watch an unlikely demonstration. An

engineering company claimed it could produce electricity simply by

wiring a nail in the trees trunk to a metal rod in the ground.

Sure enough, the demo worked but nobody knew exactly why.

Two years later, Mershin and MIT undergraduate Christopher Love

have not only figured out the source of the trees electricity,

they've joined a new company Voltree Power that wants to use that

energy to power wireless networks of environmental sensors.

As reported in PLoS ONE, the electricity stems from an acidity

difference between trees and soil. The area that is more acidic

contains a higher concentration of positively charged hydrogen

ions. Those ions attract electrons, generating a tiny current that

travels between the tree and the ground.

Using a device that extends probes underground, Voltrees invention

harvests the energy and uses it to continuously recharge a

battery, which in turn powers radio-equipped sensors. Voltree is

now working to assemble a wildfire alert network that can feed

sensor data to a central location. The devices could also monitor

climate conditions or even detect illegal radioactive materials at

the border.

While other monitoring tools have been hampered by the need for

costly solar panels or frequent battery replacements, tree-powered

sensors could be deployed over vast areas with little maintenance.

And not to worry, Mershin says: the amount of energy harvested is

so tiny that the trees wont feel a thing.?

http://voltreepower.com/bioHarvester.html

Voltree Power

100 Energy Drive

Canton, MA 02021

Tel.: +1 (781) 828-8733

Fax: +1 (781) 821-2111

E-Mail: admin@voltreepower.com

Internet: www.voltreepower.com

Mailing Address

Voltree Power

P.O. Box 477

Canton, MA 02021

Bioenergy Harvester

Voltree Power’s patented bioenergy harvester converts living plant

metabolic energy to useable electricity, providing a unique

battery replacement alternative. When coupled with our software

and low-power transceiver hardware, this technology makes

practical the deployment of large-scale, long-term sensor networks

in a variety of previously inaccessible environments, such as

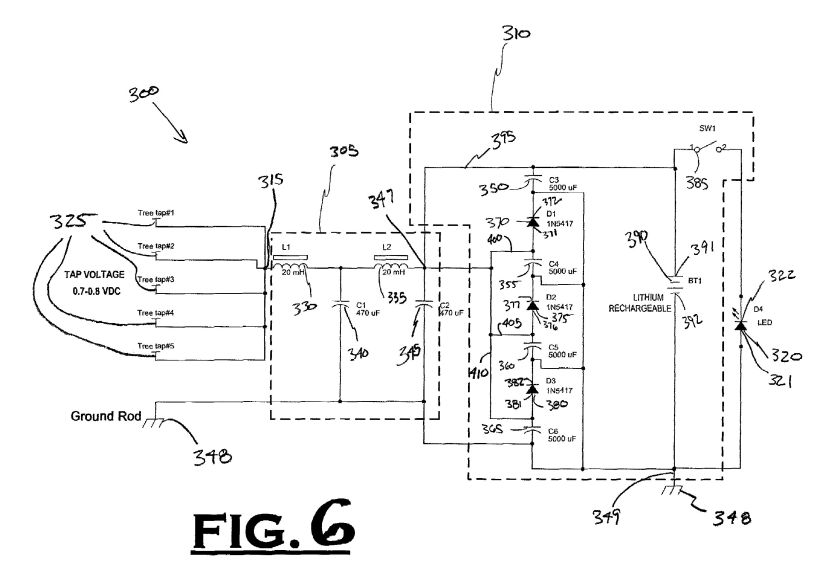

under triple-canopy or in hostile terrain. Voltree Power’s

bioenergy harvester can be used with temperature and humidity

sensors as shown below, or with a wide variety of other sensors.

Benefits of this technology include:

* Enables the use of mesh sensor technology where it would

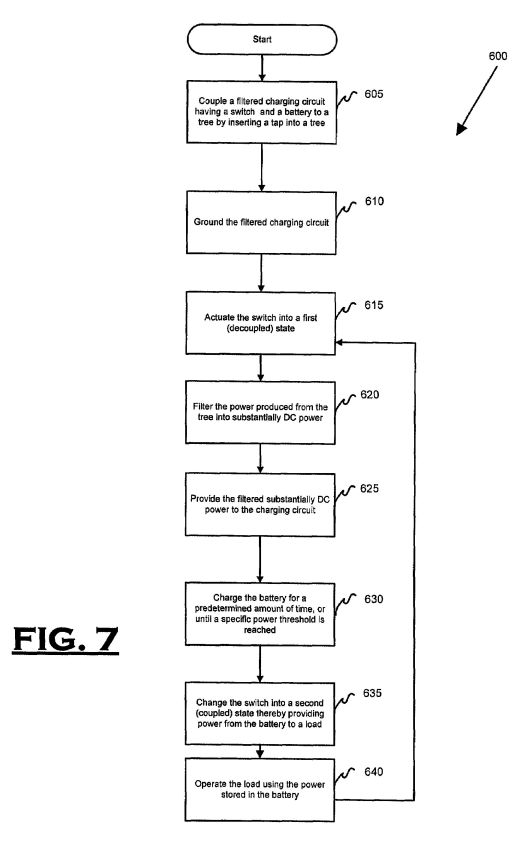

otherwise be difficult to install power devices or hard-to-reach

sensor devices for maintenance.

* Eliminates the cost of (hundreds) of thousands of batteries,

labor costs associated with battery replacement/maintenance, along

with environmental and labor costs of responsible battery

disposition/recycling.

* Does not depend on wind, light, heat gradients, or mechanical

movement.

* Weather-resistant and completely quiet.

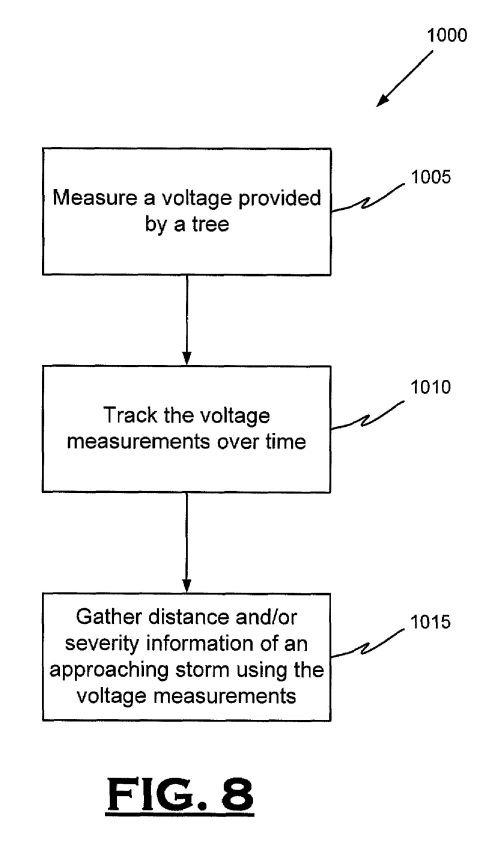

* Absence of any heat or noise signatures, making it ideal for

various covert, security-sensitive sensing applications.

* Environmentally benign to produce and operate.

* Parasitically harvests metabolic energy from any large plant

without harming it.

* Useful lifetime of the device is only limited by the

lifetime of the host.

POWER FROM A NON-ANIMAL ORGANISM

US Patent Appln 2007279014

BACKGROUND

[0002] Since the late-nineteenth century the use of, and uses for,

electricity has increased tremendously, becoming a fundamental

part of everyday life for most people. One only has to look at

remote parts of the world to see how drastically different life is

without electricity. Most electric devices in use today typically

draw between a few milliwatts to several megawatts of power,

depending on the application. Higher costs for the fuels needed to

generate electricity, and a higher electrical demand in general,

however, have led to increased electricity costs, thereby

increasing the attractiveness of alternative power sources.

[0003] One typical use of electricity is a light emitting diode

(LED). LEDs have seen increasing popularity in recent times due to

a lower per unit cost and a greater number of available colors.

LEDs are more energy efficient (i.e., less power is consumed) and

generally have a much longer life expectancy than conventional

filament-based light bulbs. In general, LEDs draw approximately 20

mA at 2V (i.e., 40 mW) when illuminated, which is far less than

conventional light bulbs.

[0004] Distribution of electricity from a generation plant to the

end-user is not a trivial problem. Thousands of miles of wires and

cables creating a transmission network are involved in delivering

power to consumers. The transmission network adds costs such as

material costs and the cost of lost energy due to the resistance

of the transmission wires. For the average consumer of

electricity, the transmission costs generally equal the cost of

the electricity itself. Furthermore, portions of the world have no

electricity because it is simply too far from the nearest

transmission line or the terrain itself prohibits installation of

transmission lines.

SUMMARY

[0005] A method for drawing electricity from a non-animal

organism, the method including coupling a first electrical

conductor to the non-animal organism, coupling a second electrical

conductor to a ground rod, embedding the ground rod into soil at a

predetermined depth as a function of a desired current level,

whereby the current available from the non-animal organism is

increased by increasing the depth that the ground rod is embedded

into the soil, coupling an electrical load between the first

electrical conductor and the second electrical conductor, the

electrical load being configured to draw electricity from the

non-animal organism via the first electrical conductor, and

operating the electrical load using electricity drawn from the

non-animal organism.

[0006] In general, in another aspect, the invention provides a

system including a non-animal organism, a first electrical

conductor electrically coupled to the non-animal organism, a

plurality of ground rods embedded into soil wherein a quantity of

the plurality of ground rods is a function of a desired current

level from the non-animal organism, whereby the current available

from the non-animal organism is increased by increasing the

quantity of the plurality of ground rods, a second electrical

conductor coupled to the plurality of ground rods, and an

electrical load coupled between the first electrical conductor and

the second electrical conductor to draw electricity from the

non-animal organism, the electrical load using electricity drawn

from the non-animal organism.

[0007] In general, in another aspect, the invention provides a

method of predicting weather using electricity from a non-animal

organism, the method including coupling a first electrical

conductor to the non-animal organism, coupling a second electrical

conductor to a ground, coupling a voltmeter between the first

electrical conductor and the second electrical conductor,

measuring a voltage potential between the first and second

electrical connectors, providing a weather prediction as a

function of the measured voltage potential.

[0008] Implementations of the invention may further include the

following features. The method of predicting weather including

determining a baseline voltage reading for the non-animal organism

under a first weather condition, determining a plurality of

voltage readings over time, comparing each of the plurality of

voltage readings to the baseline voltage reading to determine

differences between the baseline voltage reading and each of the

plurality of voltage readings, and calculating information

indicative of a second, future weather condition as a function of

the differences.

[0009] In general, in another aspect, the invention provides a

system for use with live vegetative matter growing in soil, the

system including a non-animal organism, a first electrical

conductor electrically coupled to the non-animal organism, and a

second electrical conductor coupled to the first electrical

conductor and coupled to the live vegetative matter, the second

electrical conductor providing electricity from the non-animal

organism to the live vegetative matter, wherein the growth of the

live vegetative matter is stimulated by the electricity provided

by the non-animal organism.

[0010] In general, in another aspect, the invention provides a

system including a non-animal organism, a first electrical

conductor electrically coupled to the non-animal organism, a

second electrical conductor coupled to a ground, and an electrical

load coupled between the first electrical conductor and the second

electrical conductor to draw electricity from the non-animal

organism, the electrical load using electricity drawn from the

non-animal organism, wherein the load is one of a battery, a

battery charging circuit, a sensor, a radio frequency

identification chip, a transmitter, a receiver, a global

positioning service (GPS) device, a light emitting device, and a

fire ignition system.

[0011] Implementations of the invention may include one or more of

the following features. The load is the sensor and the sensor is

one of an oxygen sensor, an air-speed sensor, a humidity sensor, a

barometric pressure sensor, a camera, a photoelectric sensor, an

altitude sensor, a smoke detector, a microphone, and a vibration

sensor. The load is the GPS device and the GPS device is one of a

GPS receiver, a GPS transmitter, a GPS guidance system, and a GPS

navigation system. The load is the light emitting device and the

light emitting device is one of a light emitting diode configured

to emit visible light, and an infrared light emitting diode

configured to emit an infrared signal.

[0012] Various aspects of the invention may provide one or more of

the following capabilities. A non-animal organism, such as a

member of the plant and/or fungi kingdom, may supply electricity

to a load. Electricity may be available in remote areas without an

electricity transmission network. Alternative "clean" electricity

can be produced. An LED may be powered from a non-animal organism.

Infra-red LEDs used in military operations may be powered. A

traffic light may be powered from a non-animal organism. A

security light may be powered from a non-animal organism.

Dependence on fossil fuels to generate electricity may be reduced.

Lighting may be provided at campgrounds and/or ski areas using

power provided from non-animal organisms. Power derived from

non-animal organisms may be used to recharge batteries in hybrid

vehicles. Advance storm warning can be obtained by measuring the

voltage provided by the non-animal organism.

[0013] These and other capabilities of the invention, along with

the invention itself, will be more fully understood after a review

of the following figures, detailed description, and claims.

BRIEF DESCRIPTION OF THE FIGURES

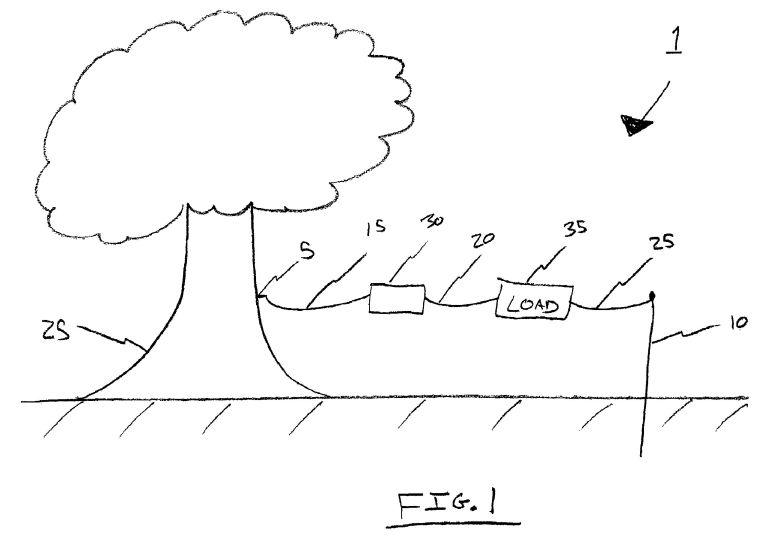

FIG. 1 is a diagram of an

apparatus for drawing power from a tree.

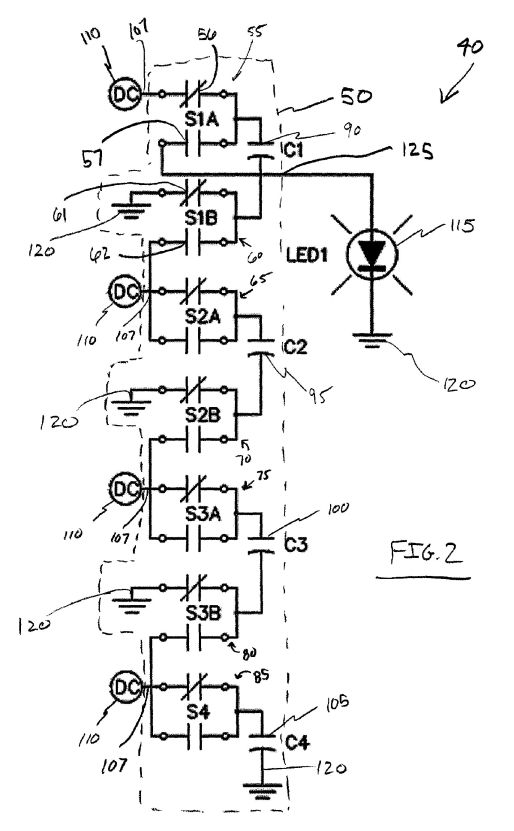

FIG. 2 is a diagram of a charging

circuit used to provide power derived from a tree to a load.

FIG. 3 is a flowchart of a

process for deriving power from a tree using the charging

circuit shown in FIG. 2.

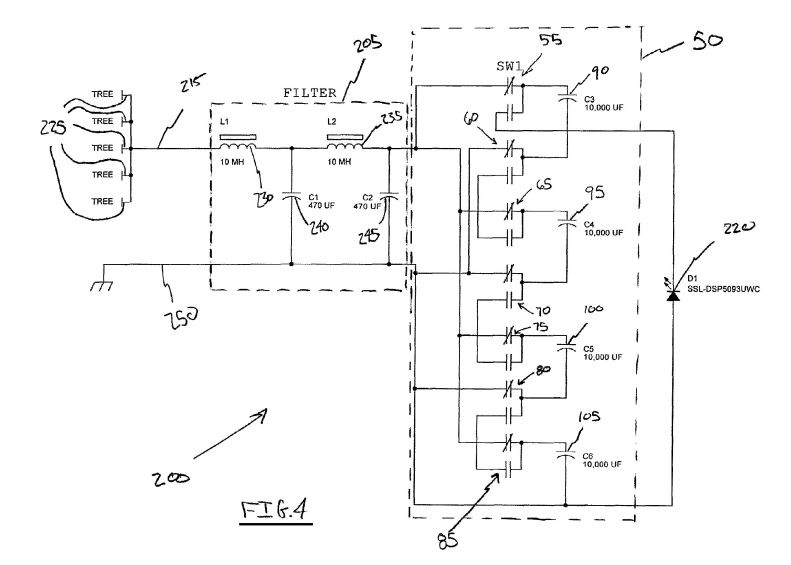

FIG. 4 is a circuit diagram of a

filtered charging circuit used in providing electricity from a

tree to a load, including the charging circuit of FIG. 2 and a

filter.

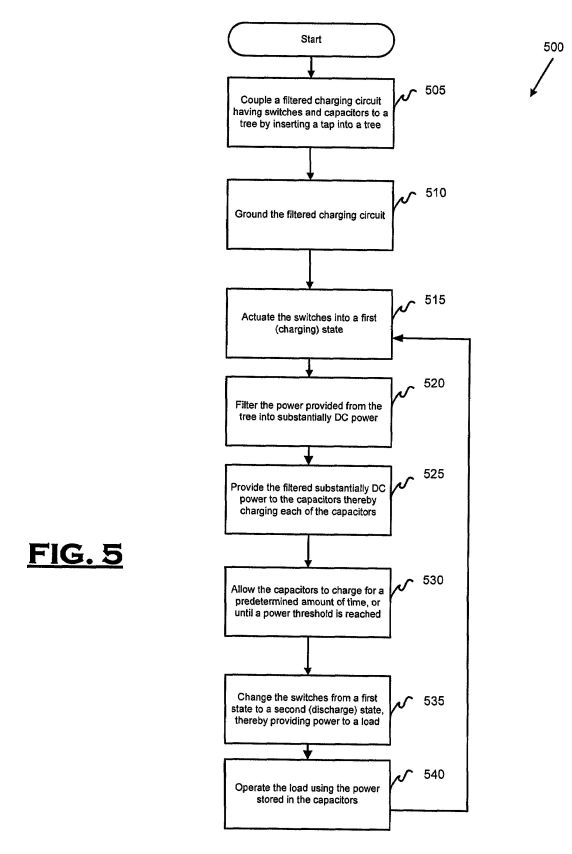

FIG. 5 is a flowchart of a

process of deriving power from a tree using the electrical

circuit shown in FIG. 4.

FIG. 6 is a circuit diagram of a

filtered charging circuit used in providing electricity from a

tree to a load and including a battery.

FIG. 7 is a flowchart of a

process of deriving power from a tree using the electrical

circuit shown in FIG. 6.

FIG. 8 is a flowchart of a

process of determining storm distance and/or severity using

voltage measurements taken from a tree.

DETAILED DESCRIPTION

[0022] Embodiments of the invention provide techniques for drawing

electricity from non-animal organisms such as members of the plant

and/or fungi kingdom, and providing the electricity to a load.

Non-animal, non-mammal organisms such as spermatophytes,

pteridophytes, succulents, Marattiales ferns, Ophioglossales

ferns, Leptosporangiate ferns, Mycophycota fungi, Zygomycota

fungi, Basidiomycota fungi, and Ascomycota fungi may be used.

Specifically, electricity can be drawn from vegetative matter such

as a living tree. The amount of available electricity has been

found to depend on the location and type of non-animal organism,

and to be approximately 0.5-2 volts DC, plus some AC current. For

example, an apparatus for using this energy includes a conductor

inserted into a tree and connected to a positive terminal of a

load. A negative conductor of the load is connected to a grounded

conductor, thereby completing a circuit. Other circuitry, such as

charging circuits and/or voltage step-up circuits, may also be

used. Other embodiments are within the scope of the invention.

[0023] Referring to FIG. 1, an apparatus 1 for deriving

electricity from a tree 25 includes a tap 5, a conductor 10, wires

15, 20, and 25, a circuit 30, and a load 35. The tap 5 is

configured to attach to, and to conduct current flow from, the

tree 25. For example, the tap 5 may be configured to be inserted

into the tree 25, although other configurations are possible

(e.g., a non-invasive transformer core that surrounds the

circumference of the tree 25). The wire 15 is electrically coupled

to the tap 5 and the circuit 30. The wire 20 is electrically

coupled to the circuit 30 and the load 35. The wire 25 is

electrically coupled to the load 35 and the conductor 10. The

conductor 10 is electrically conductive and is configured to be

inserted approximately two feet into the ground while protruding

above the ground, although the conductor 10 may be configured to

be inserted to other depths. By increasing the depth that the

conductor 10 is inserted into the ground and/or using multiple

conductors 10, the load 35 can draw more current from the tree 25.

The conductor 10 is preferably a tinned copper rod. Other

materials and/or configurations of the conductor 10 are possible.

For example the conductor 10 may be aluminum and/or connected to a

"ground" connection of a typical household electrical system. The

circuit 30 is electrically conductive and is configured to filter

the power provided by the tree, to step-up (or step-down) the

voltage supplied by the tree 25, and/or to store the power

provided by the tree 25. The circuit 30 may perform functions

other than those listed above. Also, embodiments of the apparatus

1 without the circuit 30 are possible (e.g., connecting a load

directly between the tree 25 and the conductor 10).

[0024] The load 35 can be any of a number of different devices

used for a variety of purposes. For example, the load 35 can

include a lithium battery that is charged by the tree 25, a sensor

(e.g., capable of sensing temperature, air speed, humidity,

barometric pressure, video, audio, light, vibration, altitude,

oxygen levels), a remote sensor (e.g., over a LAN, WAN, the

Internet, WiFi), a radio frequency identification (RFID) chip, a

transmitter, and/or a receiver. The load 35 can be a device for

use with a global positioning system (GPS) such as a GPS receiver,

a GPS transmitter, a GPS guidance system, and/or a GPS navigation

system. The load 35 can include a fire and/or smoke detection

system, a system configured to charge a battery powered device

(e.g., a mobile phone, a laptop computer, a portable GPS system, a

flashlight, a radio), a lighting system (e.g., for recreational

use, for military use)(including, e.g., one or more light emitting

diodes (LEDs) such as infrared LEDs), a fire ignition system

(e.g., for campground use), a weather detection and/or monitoring

system, an emergency alert/assistance beacon, a solar lighting

backup system, and/or a wireless transmission system for use with

a computer. The load 35 can include a plant (e.g., as described

below in Experiment 4).

[0025] Various embodiments of the tap 5 are possible. Preferably,

the tap 5 is a stainless steel rod, e.g., a nail, having an

outside diameter of about 0.125 inches, but other materials and

sizes are possible. For example, brass plated or aluminum rods

having an outside diameter of about 0.06 inches may be used. The

tap 5 is electrically conductive material and is preferably of a

material (e.g., stainless steel) that has a relatively high

corrosion resistance, thus inhibiting increased resistance caused

by corrosion. For extended use, the tap 5 is preferably not copper

(at least on its exterior) as this can negatively affect (e.g.,

kill) many types of trees. The tap 5 is preferably configured to

be inserted between about 0.375 inches and about 0.75 inches into

the tree 25, although other depths are possible. In trees with

thick bark, the tap 5 may be inserted further into the tree 25.

For example, if a tree has bark 1 inch thick, the tap 5 may be

inserted about 1.5 inches into the tree 25. The tap 5 is

preferably inserted into the tree 25 between about one and about

six feet above ground level, although other heights may be used.

While the apparatus 1 includes the one tap 5, multiple taps may be

used. Using multiple taps in a single tree has been found to

increase the amount of current available from the tree. The taps

may all be the same, or one or more taps may be different (e.g., a

different material, configured for different insertion depth,

etc.) than another tap.

[0026] Referring also to FIG. 2, an exemplary embodiment 40 of the

apparatus 1 including an LED load 115, and an exemplary circuit 30

that is a charging circuit 50, which includes switches 55, 60, 65,

70, 75, 80, and 85, and capacitors 90, 95, 100, and 105. The

switches 55, 60, 65, 70, 75, 80, and 85 are single-pole

double-throw (SPDT) switches. The switch 55 includes selective

connections 56 and 57. The switch 57 is connected on one side to

the switch 56 and the capacitor 90 and on its other side to an

output 125 configured to be connected to the load 115. The switch

60 also includes selective connections 61 and 62. When the

switches 55 and 60 are in a first state, the connections 56 and 61

are closed and the connections 57 and 62 are open, thereby

coupling the capacitor 90 between a power source 110 (here, a

tree) and a ground 120. When the switches 55 and 60 are in a

second state, the connections 56 and 61 are open, and the

connections 57 and 62 are closed, thereby coupling the capacitor

90 between the load LED 115, and the switch 65. Each of the

switches 55, 65, 75, and 85 are coupled to the tree 110 via the

tap 107. The switches 65, 70, 75, 80, and 85 operate as described

with respect to the switches 55 and 60.

[0027] The capacitors 90, 95, 100, and 105 are coupled to the

switches 55, 60, 65, 70, 75, 80, and 85 such that when the

switches 55, 60, 65, 70, 75, 80, and 85 are in a first state, the

circuit 50 is in a charging state and each of the capacitors 90,

95, 100, and 105 are coupled between the power source 110 and the

ground 120. When the switches 55, 60, 65, 70, 75, 80, and 85 are

in the first state the capacitors 90, 95, 100, and 105 accumulate

an electrical charge. The capacitors 90, 95, 100, and 105 are

further coupled to the switches 55, 60, 65, 70, 75, 80, and 85

such that when the switches 55, 60, 65, 70, 75, 80, and 85 are in

a second state, the circuit 50 is in a discharging state and the

capacitors 90, 95, 100, and 105 are coupled in series between the

ground 120 and a load 115 thus providing power to the load 115.

The voltage provided to the load 115 is substantially equal to the

sum of the voltages across each of the capacitors 90, 95, 100 and

105. The capacitors 90, 95, 100, and 105 are preferably about

10,000 [mu]F, but other capacitances are possible. While an LED is

shown as the load 115, other loads may be used.

[0028] While the charging circuit 50 is shown coupled to a single

tree (i.e., the tree 110), other configurations are possible. For

example, each of the switches 55, 65, 75, and 85 may be connected

to separate trees. The switches 55, 65, 75, and 85 could each be

connected to multiple trees (or other non-animal organisms). One

or more of the switches 55, 65, 75, and 85 could each be connected

to a single tree with multiple taps 107. One of the switches 55,

65, 75, and 85 could be connected to a single tree with a single

tap, with the remainder of the switches 55, 65, 75, and 85 being

connected to multiple trees, each with multiple taps. One of the

switches 55, 65, 75, and 85 could be connected to a single tree

with multiple taps, with the remainder of the switches 55, 65, 75,

and 85 being coupled to a single tree with multiple taps. Each of

the switches 55, 65, 75, and 85 may be coupled to a single tree or

multiple trees using more than one of the tap 107.

[0029] In operation, referring to FIG. 3, with further reference

to FIG. 2, a process 260 for providing power derived from a tree

to a load using the apparatus 40 includes the stages shown. The

process 260, however, is exemplary only and not limiting. The

process 260 may be altered, e.g., by having stages added, removed,

or rearranged.

[0030] At stage 264, the charging circuit 50 is coupled to the

living non-animal organism power source 110, such as a tree, a

plant, etc. Preferably, the tap 107 is inserted into the power

source 110. The tap 107 is inserted approximately 0.375 inches to

0.75 inches into the tree. Alternatively, a non-invasive tap may

be used, e.g., a transformer core can be placed around a

circumference of the tree.

[0031] At stage 268, the charging circuit 50 is grounded.

Preferably, the charging circuit 50 is coupled to a ground rod, or

other suitable electrical ground, such as a ground connection in a

typical residential power system. More current may be drawn from

the living non-animal organism by the load 115 by increasing the

depth that the ground rod is inserted into the ground and/or using

multiple ground rods.

[0032] At stage 272, the load 115 is coupled between the charging

circuit 50 and the ground 120. The load 115 is coupled on one side

to the output 125 of the charging circuit 50 and on its other side

to the ground 120.

[0033] At stage 276, the switches 55, 60, 65, 70, 75, 80, and 85

are actuated into the first (charging) state. The connections 56

and 61 of the switches 55 and 60 are closed, the connections 57

and 62 of the switches 55 and 60 are opened, and likewise for the

switches 65, 70, 75, 80, and 85. This couples the capacitors 90,

95, 100, and 105 to the taps 107.

[0034] At stage 280, the power is provided from the tree 110 to

the capacitors 90, 95, 100, and 105. The capacitors 90, 95, 100,

and 105 store energy received from the taps 107.

[0035] At stage 284, the capacitors 90, 95, 100, and 105 are

allowed to charge. The amount of time the capacitors 90, 95, 100,

and 105 are charged may vary to suit a specific application. For

example, to provide sufficient power to illuminate the LED, each

of the capacitors 90, 95, 100, and 105 is charged to 0.5 Vdc. The

amount of time for the capacitors 90, 95, 100, and 105 to reach

0.5 Vdc may vary depending on the amount of power supplied by a

particular power source.

[0036] At stage 288, the switches 55, 60, 65, 70, 75, 80, and 85

are changed from the first state to the second state to discharge

the power accumulated in the capacitors 90, 95, 100, and 105,

thereby providing power to the load 115.

[0037] The power from the capacitors 90, 95, 100, and 105 is used

to operate the load 115, here causing the LED to emit light. The

process 260 returns to stage 276 where the switches 55, 60, 65,

70, 75, 80, and 85 are changed from the second state to the first

state, thereby providing power from the taps 107 to the capacitors

90, 95, 100, and 105.

[0038] Referring to FIGS. 2 and 4, a filtered charging circuit 200

includes a filter circuit 205 and the charging circuit 50, which

are coupled to a power input 215, a load 220 (in FIGS. 2 and 4 an

LED), and a ground connector 250. The filter circuit 205 is

coupled between the power input 215 and the charging circuit 50,

and is configured to provide substantially DC power to the

charging circuit 50. The power input 215 is coupled to multiple

taps 225 configured to be inserted into one or more trees. As

described above with reference to FIG. 2, the charging circuit can

provide the load 220 with a stepped-up, substantially DC voltage.

[0039] The filter circuit 205 includes inductors 230 and 235, and

capacitors 240 and 245. The inductors 230 and 235 are coupled in

series between the power input 215 and the charging circuit 50 to

inhibit high-frequency power produced by the tree from reaching

the charging circuit 50. The capacitor 240 is coupled between the

junction of the inductors 230 and 235 and the ground 250. The

capacitor 245 is coupled between the junction of the inductor 235

and the charging circuit 50 and the ground 250. For example, the

inductors 230 and 235, and the capacitors 240 and 245 are arranged

in a 2-stage pie filter configuration. The capacitors short-out

(e.g., ground) high-frequency power produced by the tree, further

inhibiting non-DC power from being conducted to the charging

circuit 50. The inductors 230 and 235 are preferably about 10 mH,

although other inductances are possible. The capacitors 240 and

245 are preferably about 470 [mu]F, although other capacitances

are possible. The charging circuit 50 is configured to receive

substantially DC power from the filter circuit 205, and to output

intermittent DC power to the load 220 similar to the description

provided above with respect to FIG. 2.

[0040] In operation, referring to FIG. 5, with further reference

to FIG. 4, a process 500 for providing power derived from a tree

to the load 220 using the filtered charging circuit 200 includes

the stages shown. The process 500, however, is exemplary only and

not limiting. The process 500 may be altered, e.g., by having

stages added, removed, or rearranged.

[0041] At stage 505, the filtered charging circuit 200 is coupled

to the power input 215 such as a tree, a fungus, or other suitable

non-animal organism, here by inserting the taps 225 into a single

tree. Each of the taps 225 is inserted approximately 0.375 inches

to approximately 0.75 inches into the tree. If any of the taps 225

are non-invasive, then that (those) taps(s) 225 (e.g., a

transformer core) is (are) mounted accordingly. (e.g., placed

around the circumference of a tree).

[0042] At stage 510, the filtered charging circuit 200 is coupled

to ground. The filtered charging circuit 200 is connected to the

ground connector 250, such as a rod, or other suitable electrical

ground connector (e.g., a ground connection in a typical

residential power system). More current may be drawn from the

living non-animal organism by the load 220 by increasing the depth

that the ground rod is inserted into the ground and/or using

multiple ground rods.

[0043] At stage 515, the switches 55, 60, 65, 70, 75, 80, and 85

are actuated into a first (charging) state coupling the capacitors

90, 95, 100, and 105 to the filter circuit 205. Power flows from

the filter circuit 205 to the capacitors 90, 95, 100, and 105.

[0044] At stage 520, the power derived from the tree is filtered

to substantially remove alternating current (AC). At stage 520 the

filter circuit 205 filters the power derived from the taps 225

into substantially DC power. The combination of the inductors 230

and 235 and the capacitors 240 and the 245 substantially filters

out non-DC frequencies produced by the tree. The inductors 230 and

235 choke the high-frequencies produced by the tree. The

capacitors 240 and 245 inhibit low frequency power and conduct

high-frequency power to the ground connector 250. The filter

circuit 205 provides the filtered substantially DC power to the

charging circuit 50.

[0045] At stage 525 the filtered substantially DC power from the

filter circuit 205 is provided to the capacitors 90, 95, 100, and

105. The switches 55, 60, 65, 70, 75, 80, and 85 are put in the

first state to couple the circuit 205 to the capacitors 90, 95,

100, and 105 to provide power to, and charge, the capacitors 90,

95, 100, and 105. At stage 530, the capacitors 90, 95, 100, and

105 are allowed to charge. The amount of time the capacitors 90,

95, 100, and 105 are charged varies, and may be tailored to suit a

specific application. For example, to provide sufficient power to

illuminate the load 220, each of the capacitors is charged to 0.5

Vdc. The amount of time required to reach 0.5 Vdc may vary

depending on the amount of power supplied by a particular power

source.

[0046] At stage 535, the switches 55, 60, 65, 70, 75, 80, and 85

are changed from the first state to the second state to discharge

the power accumulated in the capacitors 90, 95, 100, and 105,

thereby providing power to the load 220.

[0047] After stage 535, the switches 55, 60, 65, 70, 75, 80, and

85 are actuated from the second state to the first state, thereby

providing filtered substantially DC power from the filter circuit

205 to the charging circuit 50. The stages 515, 520, 525, and 530

may be repeated.

[0048] At stage 540, the power from the capacitors 90, 95, 100,

and 105 is used to operate the load 220, here causing the LED to

emit light. The process 500 returns to stage 515 where the

switches 55, 60, 65, 70, 75, and 85 are changed from the second

state to the first state, thereby providing power from the taps

225 to the capacitors 90, 95, 100, and 105

[0049] Referring to FIG. 6, a filtered charging circuit 300

includes a filter circuit 305 and a charging circuit 310, which

are coupled to a power input 315 and a load 320 (in FIG. 6, an

LED). The filter 305 is coupled between the power input 315 and

the charging circuit 310, and is configured to provide

substantially DC power to the charging circuit 310. The power

input 315 is coupled to multiple taps 325 that are each configured

to be inserted into a tree. The load 320 is preferably a

SSL-DSP5093UWC LED (manufactured by Lumex Incorporated, of

Palatine, Ill.), although other LEDs, and other types of loads,

may be used.

[0050] The filter circuit 305 includes inductors 330 and 335,

capacitors 340 and 345, and an output node 347. The inductors 330

and 335 are coupled in series between the power input 315 and the

output node 347 and are of inductances to serve as chokes of any

high-frequencies received at the power input 315. The capacitor

340 is coupled between the junction of the inductors 330 and 335

and the ground 348. The capacitor 345 is coupled between the

output node 347 and the ground 348. For example, the inductors 330

and 335, and the capacitors 340 and 345 are arranged in a 2-stage

pie filter configuration. The inductors 330 and 335 are preferably

about 10 mH, although other inductances are possible. The

capacitors 340 and 345 work in conjunction with the inductors 330

and 335 shorting-out high frequency signals that may have passed

through the inductors 330 and 335, respectively. The capacitors

340 and 345 are preferably about 470[deg.] F., although other

capacitances are possible.

[0051] The charging circuit 310 includes capacitors 350, 355, 360,

and 365, diodes 370, 375, and 380, a switch 385, a battery 390,

and a ground connection 349 connected to the ground 348. Coupled

between the output node 347 and the ground connection 349 are the

capacitors 350, 355, 360, and 365, and the diodes 370, 375, and

380, in an alternating series of capacitors and diodes. Anodes

371, 376, and 381 of the diodes 370, 375, and 380, respectively,

are coupled to the output node 347. Cathodes 372, 377, and 382 of

the diodes 370, 375, and 380, respectively, are coupled to the

ground connection 349. The capacitor 350 is coupled between the

cathode 372 of the diode 370 and the output node 347. The

capacitor 365 is coupled between the anode 381 of the diode 380

and the ground connection 349. The capacitors 350, 355, 360, and

365, and the diodes 370, 375, and 380 act as a voltage multiplier

circuit to allow filtered substantially DC power to charge the

capacitors 350, 355, 360, and 365 (e.g., by summing the voltages

across the capacitors 350, 355, 360, and 365). Using the

capacitors 350, 355, 360, and 365, and the diodes 370, 375, and

380, a higher voltage (e.g., 2-2.5 V) is produced to charge the

battery 390. The capacitors 350, 355, 360, and 365are 5,000 [mu]F,

although other capacitances are possible, such as 10,000 [mu]F.

The diodes 370, 375, and 380 are preferably 1N5417 diodes, but

other diodes are possible.

[0052] The battery 390 is coupled between the output node 347 and

the ground 348 such that it may receive power from the output node

347. The battery 390 is preferably a lithium-ion battery, but

other batteries may be used. A positive terminal 391 of the

battery 390 is coupled to the output node 347 and the switch 385.

A negative terminal 392 of the battery 390 is coupled to the

ground 348. Other configurations are possible (e.g., coupling the

negative terminal 392 to the output node 347, and coupling the

positive terminal 391 to the ground 348).

[0053] The switch 385 is coupled between a terminal 322 of the

load 320 and output node 347 to control a power flow to the load

320. When the switch 385 is in an open state (as shown), power is

inhibited (and preferably prevented) from flowing to the load 320.

When the switch 385 is in a closed state, power may flow to the

load 320. A terminal 321 of the load 320 is coupled to the ground

348.

[0054] In operation, referring to FIG. 7, with further reference

to FIG. 6, a process 600 for providing power derived from a tree

to the load 320 using the filtered charging circuit 300 includes

the stages shown. The process 600, however, is exemplary only and

not limiting. The process 600 may be altered, e.g., by having

stages added, removed, or rearranged.

[0055] At stage 605, the filtered charging circuit 300 is coupled

to the power input 315 such as a tree, a fungus, or other suitable

non-animal organism, here by inserting the taps 325 into a single

tree. Each of the taps 325 is inserted approximately 0.375 inches

to approximately 0.75 inches into the tree. If any of the taps 325

are non-invasive, then that (those) taps(s) 325 (e.g., a

transformer core) is (are) mounted accordingly. (e.g., placed

around the circumference of a tree).

[0056] At stage 610, the filtered charging circuit 300 is coupled

to ground. The filtered charging circuit 300 is connected to the

ground connector 349, such as a rod, or other suitable electrical

ground connector (e.g., a ground connection in a typical

residential power system). More current may be drawn from the

living non-animal organism by the load 320 by increasing the depth

that the ground rod is inserted into the ground.

[0057] At stage 615, the switch 385 is actuated into the first

state (i.e., open) where the load 320 is disconnected from the

filtered charging circuit 300 and current is inhibited/prevented

from reaching/operating the LED 320.

[0058] At stage 620, the power derived from the tree is filtered

to substantially remove alternating current (AC). At stage 620 the

filter circuit 305 filters the power derived from the taps 325

into substantially DC power. The combination of the inductors 330

and 335 and the capacitors 340 and the 345 substantially filters

out non-zero frequencies produced by the tree. The inductors 330

and 335 choke the high-frequencies produced by the tree. The

capacitors 340 and 345 inhibit low frequency power and conduct

high-frequency power to the ground connector 349. The filter

circuit 305 provides the filtered substantially DC power to the

charging circuit 310.

[0059] At stage 625, the filtered substantially DC power is

provided to the charging circuit 310 via the output node 347.

Power provided from the output node 347 is conducted through the

capacitors 350, 355, 360, and 365, and the diodes 370, 375, and

380. The configuration of the diodes 370, 375, and 380 allows

substantially only filtered DC power to charge the capacitors 350,

355, 360, and 365.

[0060] At stage 630, the battery 390 is charged using power from

the output node 347 and the capacitors 350, 355, 360, and 365. The

amount of time the battery 390 is charged varies, and may be

tailored to suit a specific application. The battery 390 may be

charged for a specific predetermined amount of time, or may be

charged until a certain power threshold is reached.

[0061] At stage 635 the switch 385 is actuated into the second

state (e.g., closed) coupling the load 320 across the terminals

391 and 392 of the battery 392, thereby providing power from the

battery 390 to the LED 320. Power may also be provided to the load

320 from the output node 347 and/or the capacitors 350, 355, 360,

and 365. The stages 615, 620, 625, 630, and 635 may be repeated.

[0062] At stage 640, the power from the capacitors 350, 355, 360,

and 365, and the battery 390 is used to operate the load 320, here

causing the LED to emit light. The process 600 returns to stage

615 where the switch 385 is changed from the second state to the

first state, thereby decoupling the load 320 from the positive

terminal 391 of the battery 390, the output node 347, and the

capacitor 350. The switch 385 thus alternates between the first

state and the second state to provide intermittent power to the

LED 320. Alternatively, the switch 385 can remain in the second

state to provide substantially constant power to the LED 320.

Other modes of operation are also possible.

[0063] In operation, referring to FIG. 8, with further reference

to FIG. 1, a process 1000 for determining storm distance and/or

severity by measuring the voltage provided by the tree 25 includes

the stages shown. The process 1000, however, is exemplary only and

not limiting. The process 1000 may be altered, e.g., by having

stages added, removed, or rearranged.

[0064] At stage 1005, the voltage provided by the tree 25 is

measured using the apparatus 1. Voltage values are recorded, e.g.,

at regular time intervals such as every 30 seconds, although other

intervals are possible. Preferably, the apparatus 1 is not used to

provide power to a load (e.g., the load 35) during stage 1005,

although the apparatus 1 can provide power to a load

simultaneously with the voltage measurements. The voltage can be

measured, for example, by a computer and/or manually.

[0065] At stage 1010, the voltage measurements are tracked. For

example, a computer system can collect the voltage readings at

regular intervals and store the values in a data table with each

entry in the table representing a discrete voltage measurement at

a known time. Alternatively, a person taking manual measurements

can record the measurements manually.

[0066] At stage 1015, the voltage measurements are compared to a

baseline voltage for the tree 25 (e.g., a voltage value collected

on a clear day). If the voltage measurements decrease relative to

the baseline voltage of the tree 25, then a conclusion can be

reached and an indication can be provided that a storm (e.g., a

lightning storm) is approaching. The amount of the voltage drop

and/or the speed of the voltage drop when compared to the baseline

voltage can be used to determine the severity and/or the distance

of an approaching storm. For example, a 0.5V drop in twenty

minutes (with the baseline voltage as a reference point) can

result in a determination that a more severe storm is approaching

than a 0.2V drop in an hour (with the baseline voltage as a

reference point). The voltage readings collected and tracked at

stages 1005 and 1010 can be used at stage 1015 to determine

information about an approaching storm alone (e.g., distance

and/or severity), or can be combined with other weather tools,

such as Radar and/or satellite imagery, used in predicting weather

conditions.

Experiment 1

[0067] Referring to Appendix A, exemplary results of voltage yield

tests from different trees using different tap configurations,

different ground rod quantities, and different numbers of taps are

shown. The tests were performed using the configuration shown in

FIG. 1, and described in the corresponding written description,

where the load was a voltmeter. The circuit 30, however, as shown

in FIG. 1, was omitted in the tests. The tests were performed

selecting different geographic locations of the trees, different

types of trees, different tap materials, different tap depths,

different tap diameters, different tap heights (i.e., height from

ground level), different tree altitudes, varying numbers of taps,

and varying soil conditions. As shown in Appendix A, factors such

as the species and/or the variety of a particular plant, e.g.,

tree, affects the available voltage and/or current. For example,

an oak tree located 40 feet above sea level and a maple tree

located 200 feet above sea level provided differing amounts of

voltage and/or current. Trees produced a substantially constant DC

voltage (and some AC voltage), while other plants produced a

less-constant DC voltage than trees. Furthermore, two trees,

providing about 0.75V and 0.8V (DC), respectively, were coupled in

series. Approximately 0.8V was measured from the second of the two

tree coupled in series.

Experiment 2

[0068] The charging circuit 50 (of FIG. 2) was used to

successfully power an LED. The charging circuit 50, using four

10,000 [mu]F (35 Vdc) capacitors, successfully illuminated an

SSL-DSP5093UWC LED (manufactured by Lumex Incorporated, of

Palatine, Ill.) for approximately one second. The charging circuit

50 was placed in the charging state for approximately 1.75 hours,

thereby charging the capacitors 90, 95, 100, and 105. At the end

of the charging period, there was approximately a 0.5 Vdc

potential in each of the capacitors 90, 95, 100, and 105, storing

approximately 0.0125 Joules of energy in each of the capacitors

90, 95, 100, and 105. To light the LED, the switches 55, 60, 65,

70, 75, 80, and 85 were actuated, changing the switches 55, 60,

65, 70, 75, 80, and 85 from the first (charging) state, to the

second (discharge) state, thereby providing 2 Vdc to the LED

(4*0.5 Vdc) and illuminating the LED. After approximately one

second of the LED being illuminated, the voltage across the LED

dropped to 1.5 Vdc and the LED no longer illuminated (the lower

operating threshold of the SSL-DSP5093UWC LED is approximately

1.5V). The capacitors 90, 95, 100, and 105 were allowed to

recharge for approximately one hour to again reach a 0.5 Vdc

potential across each of the capacitors 90, 95, 100, and 105.

Experiment 3

[0069] The apparatus was used to collect weather related

information (exemplary data is shown in Appendix B). Voltage

readings were collected as a lightning storm approached from the

West of a test site including a tree. As the storm approached the

test site, a voltage provided by the tree decreased relative to

prior levels. The closer the storm was relative to the test site,

the larger the voltage drop. For example, when the storm was

several miles away, the voltage provided by the tree dropped about

0.2V compared to a voltage measured from the tree on a clear day.

As the storm had substantially reached the test site, the voltage

provided by the tree had dropped approximately 0.5V compared to

the voltage measured from the tree on a clear day. The approaching

storm was an intense lightning storm, including positive

lightning. Data consistent with the above description was recorded

during other lightning storms. Observations indicate that stronger

electrical activity (e.g., lightning) produced by a storm caused a

quicker and larger voltage drop. Thus, by measuring the voltage

provided by the tree 25, it was possible to gather information

regarding the severity of an approaching storm. After a storm had

passed over the test site, the voltage provided by the tree would

return to "normal" levels within about thirty-five to forty

minutes.

Experiment 4

[0070] A modified version of the apparatus 1 shown in FIG. 1 was

used to stimulate/enhance the growth of plants including tomato

and broccoli plants. Providing electricity produced by a tree to a

plant was found to increase growth of the plant, to increase the

plant's resistance to pests, and to increase the plant's

resistance to frost. A tree was coupled to a plant using the tap 5

and the wire 15, with the plant being the load 35. The plant's

root system replaced the conductor 10.

Broccoli Plant

[0071] One of several broccoli plants in a group near each other

was coupled to an apple tree as described above during an entire

growing season. Prior to coupling the apple tree to the broccoli

plant, the apple tree produced about 1.1 Vdc and the broccoli

plant produced an average of about 0.3 Vdc. As the growing season

progressed, the "energized" broccoli plant showed increased growth

and increased resistance to pests relative to the other

neighboring broccoli plants. For example, the energized broccoli

plant grew taller than the other neighboring broccoli plants, and

produced a larger center head and more side heads than the other

neighboring broccoli plants. An additional experiment was

performed by energizing the smallest and weakest broccoli plant of

the group of broccoli plants. Within about two to three days of

being energized, the newly-energized broccoli plant was about the

same size and height as the neighboring non-energized broccoli

plants.

[0072] The energized broccoli plant was not bothered by pests,

whereas the non-energized broccoli plants were attacked by pests.

As determined by several visual inspections during the growing

season, the energized broccoli plant was substantially untouched

by pests, whereas the non-energized broccoli plants' leaves were

eaten by pests. As a further experiment, a worm was placed on the

energized broccoli plant and then onto one of the other broccoli

plants. After being placed on the "energized" broccoli plant, the

worm did not eat the broccoli plant and fell off. When the same

worm was placed on the non-energized broccoli plant, the worm

began eating the broccoli plant soon thereafter. An additional

experiment was performed by energizing a pest-inhabited broccoli

plant. Within about one hour of being energized, the pests

inhabiting the broccoli plant vacated the plant.

Tomato Plant

[0073] One of several Cherokee Purple tomato plants in a group

near each other was coupled to an elm tree. Prior to coupling the

elm tree to the tomato plant, the elm tree produced about 1.2 Vdc.

The energized/connected tomato plant included four shoots, each of

which were coupled to the elm tree. Visual inspections of the

tomato plant revealed that the energized tomato plant grew

approximately thirty-three percent higher than the non-energized

plants. The energized tomato plant also produced more tomatoes

than the non-energized tomato plants. Furthermore, the energized

tomato plant survived the first two frosts of the winter season,

whereas the non-energized tomato plants died after the first

frost.

[0074] Other embodiments are within the scope and spirit of the

invention, including the appended claims. Features implementing

functions may be physically located at various positions,

including being distributed such that portions of functions are

implemented at different physical locations. Loads other than LEDs

may be used, such as a transmitter, receiver, microchip,

incandescent light source, infrared light source, a laser, a DC/DC

voltage converter, a DC/AC inverter, etc. Power may be drawn from

non-animal organisms other than trees. For example, broccoli

plants, tomato plants, soybean plants, and mushrooms may be used.

Also, potted plants, and potted trees may be used. The tap may be

inserted into a branch of the tree. The load can draw more current

from the tree using multiple ground rods.

[0075] While the tap has been disclosed as a nail, other

configurations are possible such as a staple. Non-invasive

embodiments of the tap are possible, e.g., a donut-shaped

transformer core placed around the circumference of a tree. The

surface area of a tap may be increased by, for example, being

threaded (e.g., being a screw) and/or placing outwardly disposed

barbs on the tap. A tap may have a flange disposed around the

circumference of the tap to help a user insert the tap correctly

into a tree (e.g., to the correct depth). A tap may include a

handle to help in insertion into the tree and/or removal from the

tree.

[0076] While the terms "connected," "connector," "coupled," and

"connection" have been used to indicate a direct connection, other

configurations are possible. For example, referring to FIG. 6,

when the diode 380 is "coupled" to the capacitor 360, this may

include indirect connection through another component (e.g., a

resistor coupled between the cathode 382 of the diode 380 and the

capacitor 360).

[0077] The word "or" is to be construed as including the

conjunctive and disjunctive definition.

[0078] Further, while the description refers to the invention, the

description may include more than one invention.

APPENDIX A

POWER SOURCE

DATA COLLECTION Height

Test Time Voltage Nail

Penetration Nail from No. of

No. Intervals DC Tree Type Nail Type

Depth Diameter Ground Nails Soil

Type Altitude

1 7:00 PM 0.9 VDC PINE STAINLESS

[3/4]'' [1/8]'' 3 FT 2 LOAM

2 7:25 0.9 VDC PINE STAINLESS

[3/4]'' [1/8]'' 4 FT 2 LOAM

3 7:40 0.9 VDC PINE STAINLESS

[3/4]'' [1/8]'' 5 FT 2 LOAM

1 1:00 PM 1.0 VDC PINE STAINLESS

[3/4]'' [1/8]'' 5 FT 2 CLAY-SAND

1 10 MIN -1.2 EIM [3/4]''

[3/8] 18'' 1 SAND 40

2 -1.6 BLUE SPRUCE [3/4]''

[3/8] 18'' 1 SAND 40

3 -1.0 MAPLE [3/4]''

[3/8] 18'' 1 SAND 40

4 -1.1 MAPLE [3/4]''

[3/8] 18'' 1 SAND 40

5 -1.2 EIM [3/4]''

[3/8] 18'' 1 SAND 40

6 -1.1 WALNUT [3/4]''

[3/8] 18'' 1 SAND 40

7 -0.8 LILAC BUSH [3/4]''

[3/8] 18'' 1 SAND 40

8 -1.1 ELM [3/4]''

[3/8] 18'' 1 SAND 40

9 -1.6 BLUE SPRUCE [3/4]''

[3/8] 18'' 1 SAND 40

10 -1.1 MAPLE [3/4]''

[3/8] 18'' 1 SAND 40

11 -1.1 MAPLE [3/4]''

[3/8] 18'' 1 SAND 40

12 -1.4 BIRCH [3/4]''

[3/8] 18'' 1 SAND 40

13 -1.4 BIRCH [3/4]''

[3/8] 36'' 1 SAND 40

14 -1.5 BIRCH [3/4]''

[3/8] 2'' 1 SAND 40

15 -1.2 OAK [3/4]''

[3/8] 18'' 4 SAND 40

16 -1.2 ELM [3/4]''

[3/8] 18'' 1 SAND 40

17 -1.5 APPLE [3/4]''

[3/8] 18'' 1 SAND 40

18 -1.5 APPLE [3/4]''

[3/8] 36'' 1 SAND 40

19 -1.3 OAK [3/4]''

[3/8] 18'' 1 SAND 40

20 -1.2 MAPLE [3/4]''

[3/8] 18'' 1 SAND 40

21 -0.8 ? BUSH [3/4]''

[3/8] 12'' 1 SAND 40

22 -1.1 ELDER [3/4]''

[3/8] 18'' 1 SAND 40

23 -1.6 SPRUCE [3/4]''

[3/8] 18'' 1 SAND 40

24 -1.2 OAK [3/4]''

[3/8] 18'' 1 SAND 40

25 -1.1 GREEN [3/4]''

[3/8] 18'' 1 SAND 40

26 -1.1 SPRUCE [3/4]''

[3/8] 36'' 1 SAND 40

27 -1.1 [3/4]''

[3/8] 48'' 1 SAND 40

28 -1.1 [3/4]''

[3/8] 8'' 1 SAND 40

29 -1.1 [3/4]''

[3/8] 2'' 1 SAND 40

30 -1.1 [3/4]''

[3/8] 4'' 1 SAND 40

31 -1.0 BIRCH [3/4]''

[3/8] 18'' 1 SAND 40

32 -1.0 BIRCH [3/4]''

[3/8] 12'' 1 SAND 40

33 -1.0 BIRCH [3/4]''

[3/8] 5'' 1 SAND 40

34 -1.1 MAPLE [3/4]''

[3/8] 18'' 1 SAND 40

35 -1.4 OAK [3/4]''

[3/8] 18'' 1 SAND 40

36 -0.9 ? [3/4]''

[3/8] 12'' 1 SAND 40

37 1.1 ELM [3/4]''

[3/8] 18'' 1 SAND 40

38 1.2 ELM [3/4]'' [1/4] to

[3/8] 18'' 1 SAND APPOX 60

39 1.1 OAK [3/4]'' [1/4] to

[3/8] 18'' 1 SAND APPOX 60

40 1.1 OAK [3/4]'' [1/4] to

[3/8] 18'' 1 SAND APPOX 60

41 1.2 ELM [3/4]'' [1/4] to

[3/8] 18'' 1 SAND APPOX 60

42 1.0 BIRCH [3/4]'' [1/4] to

[3/8] 18'' 1 SAND APPOX 60

43 1.2 MAPLE [3/4]'' [1/4] to

[3/8] 18'' 1 SAND APPOX 60

44 1.4 BLUE SPRUCE [3/4]''

[1/4] to [3/8] 18'' 1 SAND

APPOX 60

45 1.1 ELM [3/4]'' [1/4] to

[3/8] 18'' 1 SAND APPOX 60

45 1.3 MAPLE [3/4]'' [1/4] to

[3/8] 18'' 1 SAND APPOX 60

47 1.1 MAPLE [3/4]'' [1/4] to

[3/8] 18'' 1 SAND APPOX 60

48 -1.2 APPLE [3/4]'' [1/4] to

[3/8] 18'' 5 SAND 40

49 -1.2 APPLE [3/4]'' [1/4] to

[3/8] 30'' 4 SAND 40

50 -1.3 WILLOW [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 40

51 -1.3 WILLOW [3/4]'' [1/4]

to [3/8] 24'' 1 SAND 40

52 -1.3 WILLOW [3/4]'' [1/4]

to [3/8] 36'' 1 SAND 40

53 -1.0 MAPLE [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 40

54 -1.1 MAPLE [3/4]'' [1/4] to

[3/8] 0'' 1 SAND 40

55 -1.2 ELM [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 40

56 1.3 OAK [3/4]'' [1/4] to

[3/8] 18'' 1 SAND CLAY 120

57 1.1 ELM [3/4]'' [1/4] to

[3/8] 18'' 1 SAND CLAY 120

58 1.4 SASAFRAS [3/4]'' [1/4]

to [3/8] 18'' 1 SAND CLAY 120

59 1.0 OAK [3/4]'' [1/4] to

[3/8] 18'' 1 SAND CLAY 120

60 1.0 OAK [3/4]'' [1/4] to

[3/8] 38'' 1 SAND CLAY 120

61 1.2 OAK [3/4]'' [1/4] to

[3/8] 0'' 1 SAND CLAY

120

62 1.3 SPRUCE [3/4]'' [1/4] to

[3/8] 18'' 1 SAND CLAY 120

63 1.4 SPRUCE [3/4]'' [1/4] to

[3/8] 30'' 1 SAND CLAY 120

64 1.2 MAPLE [3/4]'' [1/4] to

[3/8] 18'' 1 SAND CLAY 120

65 1.1 CEDAR [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 40

66 1.4 CHERRY [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 40

67 1.4 CHERRY [3/4]'' [1/4] to

[3/8] 12'' 1 SAND 40

68 1.5 CHERRY [3/4]'' [1/4] to

[3/8] 0'' 1 SAND 40

69 1.4 CHERRY [3/4]'' [1/4] to

[3/8] 36'' 1 SAND 40

70 1.1 CEDAR [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 40

71 1.2 MAPLE [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 40

72 1.2 MAPLE [3/4]'' [1/4] to

[3/8] 36'' 1 SAND 40

73 1.3 MAPLE [3/4]'' [1/4] to

[3/8] 0'' 1 SAND 40

112 0.9 CEDAR [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 40'

113 0.9 CEDAR [3/4]'' [1/4] to

[3/8] 36'' 1 SAND 40'

114 1.0 CEDAR [3/4]'' [1/4] to

[3/8] 0'' 1 SAND 40'

115 1.0 CEDAR [3/4]'' [1/4] to

[3/8] 0'' 1 SAND 40'

116 1.3 OAK [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 200'

117 1.3 OAK [3/4]'' [1/4] to

[3/8] 24'' 1 SAND 200'

118 1.3 OAK [3/4]'' [1/4] to

[3/8] 48'' 1 SAND 200'

119 1.3 OAK [3/4]'' [1/4] to

[3/8] 0'' 1 SAND 200'

120 1.1 MAPLE [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 200'

121 1.1 MAPLE [3/4]'' [1/4] to

[3/8] 24'' 1 SAND 200'

122 1.2 MAPLE [3/4]'' [1/4] to

[3/8] 0'' 1 SAND 200'

123 1.4 SPRUCE [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 200'

124 1.5 SPRUCE [3/4]'' [1/4]

to [3/8] 0'' 1 SAND 200'

125 1.2 OAK [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 200'

126 1.2 OAK [3/4]'' [1/4] to

[3/8] 24'' 1 SAND 200'

127 1.3 OAK [3/4]'' [1/4] to

[3/8] 0'' 1 SAND 200'

128 1.0 MAPLE [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 200'

129 1.0 MAPLE [3/4]'' [1/4] to

[3/8] 24'' 1 SAND 200'

130 1.0 MAPLE [3/4]'' [1/4] to

[3/8] 36'' 1 SAND 200'

131 1.1 MAPLE [3/4]'' [1/4] to

[3/8] 0'' 1 SAND 200'

132 -1.2 MAPLE [3/4]'' [1/4]

to [3/8] 24'' 1 SAND 200'

133 -1.2 MAPLE [3/4]'' [1/4]

to [3/8] 24'' 4 SAND 200'

134 -1.2 ELM [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 200'

135 -1.2 ELM [3/4]'' [1/4] to

[3/8] 30'' 1 SAND 200'

136 -1.3 ELM [3/4]'' [1/4] to

[3/8] 44'' 8 SAND 200'

137 -1.2 ELM [3/4]'' [1/4] to

[3/8] 60'' 1 SAND 200'

138 -1.4 SPRUCE [3/4]'' [1/4]

to [3/8] 8'' 1 SAND 200'

139 1.2 ELM [3/4]'' [1/4] to

[3/8] 20'' 1 SAND 140'

140 1.2 ELM [3/4]'' [1/4] to

[3/8] 28'' 1 SAND 140'

141 1.2 ELM [3/4]'' [1/4] to

[3/8] 36'' 1 SAND 140'

142 1.4 ELM [3/4]'' [1/4] to

[3/8] 0'' 1 SAND 140'

143 1.6 SPRUCE [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 140'

144 1.6 SPRUCE [3/4]'' [1/4]

to [3/8] 30'' 1 SAND 140'

145 1.4 SPRUCE [3/4]'' [1/4]

to [3/8] 0'' 1 SAND 140'

146 1.1 MAPLE [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 140'

147 1.1 MAPLE [3/4]'' [1/4] to

[3/8] 24'' 1 SAND 140'

148 1.1 MAPLE [3/4]'' [1/4] to

[3/8] 46'' 1 SAND 140'

149 1.3 MAPLE [3/4]'' [1/4] to

[3/8] 0'' 1 SAND 140'

150 1.1 OAK [3/4]

[1/4]-[3/8] 18'' SAND

140'

151 1.1 OAK [3/4]

[1/4]-[3/8] 28'' SAND

CLAY 140'

152 1.1 OAK [3/4]

[1/4]-[3/8] 38'' SAND

CLAY 140'

153 1.2 OAK [3/4]

[1/4]-[3/8] 49'' SAND

CLAY 140'

154 1.2 OAK [3/4]

[1/4]-[3/8] 0'' SAND

CLAY 140'

155 0.9 RED OAK [3/4]

[1/4]-[3/8] 18'' 1 SAND CLAY

140'

156 0.9 RED OAK [3/4]

[1/4]-[3/8] 30'' 1 SAND CLAY

140'

157 0.8 RED OAK [3/4]

[1/4]-[3/8] 56'' 1 SAND CLAY

140'

158 1.1 RED OAK [3/4]

[1/4]-[3/8] 0'' 1 SAND

CLAY 140'

159 1.2 SUGAR MAPLE [3/4]

[1/4]-[3/8] 18'' 1 SAND CLAY

140'

160 1.2 SUGAR MAPLE [3/4]

[1/4]-[3/8] 25'' 1 SAND CLAY

140'

161 1.3 SUGAR MAPLE [3/4]

[1/4]-[3/8] 0'' 1 SAND

CLAY 140'

162 1.4 SUGAR MAPLE [3/4]

[1/4]-[3/8] 18'' 1 SAND CLAY

140'

163 1.2 BLACK CHERRY [3/4]

[1/4]-[3/8] 17'' 1 SAND CLAY

140'

164 1.2 BLACK CHERRY [3/4]

[1/4]-[3/8] 25'' 1 SAND CLAY

140'

165 1.3 BLACK CHERRY [3/4]

[1/4]-[3/8] 0'' 1 SAND

CLAY 140'

166 1.4 BLACK CHERRY [3/4]

[1/4]-[3/8] 20'' 12 SAND

CLAY 140'

167 1.4 PEAR [3/4]

[1/4]-[3/8] 0'' 1 SAND

CLAY 140'

168 1.1 PEAR [3/4]

[1/4]-[3/8] 18'' 1 SAND CLAY

140'

169 1.1 WILLOW [3/4]

[1/4]-[3/8] 27'' 1 SAND CLAY

140'

170 1.3 WILLOW [3/4]

[1/4]-[3/8] 0'' 1 SAND

CLAY 140'

171 1.6 WILLOW [3/4]

[1/4]-[3/8] 18'' 1 SAND CLAY

140'

172 1.1 SPRUCE [3/4]

[1/4]-[3/8] 20'' 1 SAND CLAY

140'

173 1.1 BEECH [3/4]

[1/4]-[3/8] 30'' 1 SAND 40'

174 1.1 BEECH [3/4]

[1/4]-[3/8] 40'' 1 SAND 40'

175 1.1 BEECH [3/4]

[1/4]-[3/8] 50'' 1 SAND 40'

176 1.0 BEECH 3 inch

[1/4]-[3/8] 20'' 1 SAND 40'

177 1.0 BEECH 5 inch

[1/4]-[3/8] 20'' 1 SAND 40'

178 1.2 BEECH staple

[1/4]-[3/8] 20'' 1 SAND 40'

179 1.0 ELM [3/4]

[1/4]-[3/8] 18'' 1 SAND 40'

180 1.0 ELM 3 inch

[1/4]-[3/8] 36'' 1 SAND 40'

181 0.9 ELM 5 inch

[1/4]-[3/8] 36'' 1 SAND 40'

182 1.2 ELM staple

[1/4]-[3/8] 36'' 1 SAND 40'

183 1.1 BIRCH [3/4]

[1/4]-[3/8] 18'' 1 SAND 40'

184 1.3 ELM [3/4]

[1/4]-[3/8] 18'' 1 SAND 140'

185 1.3 ELM [3/4]

[1/4]-[3/8] 36'' 1 SAND 140'

186 1.4 ELM [3/4]

[1/4]-[3/8] 0'' 1 SAND

140'

187 1.4 SPRUCE [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 140

188 1.4 SPRUCE [3/4]'' [1/4]

to [3/8] 34'' 1 SAND 140

189 1.5 SPRUCE [3/4]'' [1/4]

to [3/8] 0 1 SAND 140

190 1.3 OAK [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 140

191 1.3 OAK [3/4]'' [1/4] to

[3/8] 36'' 1 SAND 140

192 1.3 OAK [3/4]'' [1/4] to

[3/8] 48'' 1 SAND 140

193 1.4 OAK [3/4]'' [1/4] to

[3/8] 0 1 SAND 140

194 1.3 APPLE? [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 140

195 1.3 APPLE [3/4]'' [1/4] to

[3/8] 30'' 1 SAND 140

196 1.1 PINE [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 140

197 1.1 PINE [3/4]'' [1/4] to

[3/8] 36'' 1 SAND 140

198 1.0 MAPLE [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 40

199 1.0 MAPLE [3/4]'' [1/4] to

[3/8] 36'' 1 SAND 40

200 1.2 BLACK CHERRY [3/4]''

[1/4] to [3/8] 12'' 1 SAND 40

201 1.2 BLACK CHERRY [3/4]''

[1/4] to [3/8] 20'' 1 SAND 40

202 1.2 BLACK CHERRY [3/4]''

[1/4] to [3/8] 48'' 1 SAND 40

203 1.3 BLACK CHERRY [3/4]''

[1/4] to [3/8] 0 1 SAND 40

204 1.1 LILAC [3/4]'' [1/4] to

[3/8] 14'' 1 SAND 40

205 1.1 LILAC [3/4]'' [1/4] to

[3/8] 22'' 1 SAND 40

206 1.1 LILAC [3/4]'' [1/4] to

[3/8] 40'' 1 SAND 40

207 1.1 ELM [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 40

208 1.1 ELM [3/4]'' [1/4] to

[3/8] 36'' 1 SAND 40

209 1.1 ELM [3/4]'' [1/4] to

[3/8] 50'' 1 SAND 40

210 1.3 SPRUCE [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 40

211 1.3 SPRUCE [3/4]'' [1/4]

to [3/8] 30'' 1 SAND 40

212 1.3 SPRUCE [3/4]'' [1/4]

to [3/8] 50'' 1 SAND 40

213 1.3 SPRUCE [3/4]'' [1/4]

to [3/8] 74'' 1 SAND 40

214 -1.2 ELM [3/4]'' [1/4] to

[3/8] 20'' 8 SAND 40

215 -1.2 ELM [3/4]'' [1/4] to

[3/8] 36'' 1 SAND 40

216 -1.3 ELM [3/4]'' [1/4] to

[3/8] 0 1 SAND 40

217 -1.1 MAPLE [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 40

218 -1.3 APPLE [3/4]'' [1/4]

to [3/8] 14'' 1 SAND 40

219 -1.3 APPLE [3/4]'' [1/4]

to [3/8] 25'' 1 SAND 40

220 -1.3 APPLE [3/4]'' [1/4] to

[3/8] 50'' 1 SAND 40

221 -1.4 SPRUCE [3/4]'' [1/4]

to [3/8] 14'' 1 SAND 40

222 -1.4 SPRUCE [3/4]'' [1/4]

to [3/8] 22'' 1 SAND 40

223 -1.4 SPRUCE [3/4]'' [1/4]

to [3/8] 36'' 1 SAND 40

224 -1.1 MAPLE [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 40

225 -1.1 MAPLE [3/4]'' [1/4]

to [3/8] 36'' 1 SAND 40

226 -1.0 ELM [3/4]'' [1/4] to

[3/8] 20'' 1 SAND 40

227 -1.0 ELM [3/4]'' [1/4] to

[3/8] 40'' 1 SAND 40

228 -1.0 ELM [3/4]'' [1/4] to

[3/8] 50'' 1 SAND 40

229 -1.2 BEECH [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 40

230 -1.2 BEECH [3/4]'' [1/4]

to [3/8] 24'' 1 SAND 40

231 -1.2 BEECH [3/4]'' [1/4]

to [3/8] 38'' 1 SAND 40

232 -1.3 OAK [3/4]'' [1/4] to

[3/8] 16'' 1 SAND 40

233 -1.3 OAK [3/4]'' [1/4] to

[3/8] 28'' 1 SAND 40

234 -1.3 OAK [3/4]'' [1/4] to

[3/8] 38'' 1 SAND 40

235 -1.4 OAK [3/4]'' [1/4] to

[3/8] 0 1 SAND 40

236 -1.2 BIRCH [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 40

237 -1.3 BIRCH [3/4]'' [1/4]

to [3/8] 30'' 1 SAND 40

238 -1.3 BIRCH [3/4]'' [1/4]

to [3/8] 44'' 1 SAND 40

239 -1.2 BIRCH [3/4]'' [1/4]

to [3/8] 0 1 SAND 40

240 -1.1 POPLAR [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 40

241 -1.1 POPLAR [3/4]'' [1/4]

to [3/8] 24'' 1 SAND 40

242 -1.2 POPLAR [3/4]'' [1/4]

to [3/8] 36'' 1 SAND 40

243 -1.2 POPLAR [3/4]'' [1/4]

to [3/8] 48'' 1 SAND 40

244 -1.1 ELM [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 40

245 -1.1 ELM [3/4]'' [1/4] to

[3/8] 28'' 1 SAND 40

246 -1.2 BLACKBERRY [3/4]''

[1/4] to [3/8] ?10''? 1 SAND

40

247 -1.2 BLACKBERRY [3/4]''

[1/4] to [3/8] 16'' 1 SAND 40

248 -0.9 WILLOW [3/4]'' [1/4]

to [3/8] 12'' 1 SAND 40

249 -1.0 WILLOW [3/4]'' [1/4]

to [3/8] 20'' 1 SAND 40

250 -1.1 WILLOW [3/4]'' [1/4]

to [3/8] 0 1 SAND 40

251 -0.8 BROCOLLI [3/4]''

[1/4] to [3/8] 8'' 1

SAND 40

252 -0.7 BROCOLLI [3/4]''

[1/4] to [3/8] LEAF 1 SAND 40

253 -1.1 ELM [3/4]'' [1/4] to

[3/8] 14'' 1 SAND 40

254 -1.1 ELM [3/4]'' [1/4] t0

[3/8] 20'' 1 SAND 40

255 -1.0 ELM [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 40

256 -1.0 ELM [3/4]'' [1/4] to

[3/8] 36'' 1 SAND 40

257 -1.1 WALNUT [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 40

258 -0.3 WALNUT [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 40

259 -0.4 PINE [3/4]'' [1/4] to

[3/8] 16'' 1 SAND 40

260 -0.9 PINE [3/4]'' [1/4] to

[3/8] 0 1 SAND 40

261 -1.2 PINE [3/4]'' [1/4] to

[3/8] 20'' 1 SAND 40

262 -1.2 PINE [3/4]'' [1/4] to

[3/8] 40'' 1 SAND 40

263 -1.3 PINE [3/4]'' [1/4] to

[3/8] 0 1 SAND 40

264 -1.1 LILAC [3/4]'' [1/4]

to [3/8] 12'' 1 SAND 40

265 -1.1 LILAC [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 40

266 -1.0 MAPLE [3/4]'' [1/4]

to [3/8] 2'' 1 SAND 40

267 -1.0 MAPLE [3/4]'' [1/4]

to [3/8] 0 1 SAND 40

268 -1.1 PINE [3/4]'' [1/4] to

[3/8] 18'' 1 SAND 40

269 -1.0 PINE [3/4]'' [1/4] to

[3/8] 32'' 1 SAND 40

270 -1.3 LEMON [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 40

271 -0.9 TOMATO [3/4]'' [1/4]

to [3/8] 6'' 1 SAND 40

272 -0.8 CAULIFLOWER [3/4]''

[1/4] to [3/8] 2'' 1

SAND 40

273 0.0 GRASS [3/4]'' [1/4] to

[3/8] 0 Alligator SAND 40

clip

274 -1.1 PINE [3/4]'' [1/4] to

[3/8] 16'' 1 SAND 40

275 -1.1 MAPLE [3/4]'' [1/4]

to [3/8] 15'' 1 SAND 40

276 -1.1 MAPLE [3/4]'' [1/4]

to [3/8] 28'' 1 SAND 40

277 -1.0 MAPLE [3/4]'' [1/4]

to [3/8] 36'' 1 SAND 40

278 -1.0 ELM [3/4]'' [1/4] to

[3/8] 25'' 1 SAND 40

279 -1.1 ELM [3/4]'' [1/4] to

[3/8] 35'' 1 SAND 40

280 -0.9 MAPLE [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 40

281 -1.0 MAPLE [3/4]'' [1/4]

to [3/8] 36'' 1 SAND 40

282 -1.0 CEDAR [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 40

283 -1.1 CEDAR [3/4]'' [1/4]

to [3/8] 30'' 1 SAND 40

284 -1.0 BASSWOOD [3/4]''

[1/4] to [3/8] 20'' 1 SAND 40

285 -1.0 BASSWOOD [3/4]''

[1/4] to [3/8] 36'' 1 SAND 40

286 -1.0 BASSWOOD [3/4]''

[1/4] to [3/8] 48'' 1 SAND 40

287 -1.0 BASSWOOD [3/4]''

[1/4] to [3/8] 65'' 1 SAND 40

290 0.0 TELE POLE [3/4]''

[1/4] to [3/8] 24'' 1 SAND 40

291 -0.9 LILAC [3/4]'' [1/4]

to [3/8] 16'' 1 SAND 40

293 -1.4 SPRUCE [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 40

294 -1.4 SPRUCE [3/4]'' [1/4]

to [3/8] 28'' 1 SAND 40

295 -1.3 SPRUCE [3/4]'' [1/4]

to [3/8] 40'' 1 SAND 40

296 -1.1 ELM [3/4]'' [1/4] to

[3/8] 16'' 1 SAND 40

297 -1.2 APPLE [3/4]'' [1/4]

to [3/8] 16'' 1 SAND 40

298 -1.2 APPLE [3/4]'' [1/4]

to [3/8] 24'' 1 SAND 40

299 -1.1 MAPLE [3/4]'' [1/4]

to [3/8] 18'' 1 SAND 40

300 -1.1 MAPLE [3/4]'' [1/4]

to [3/8] 30'' 1 SAND 40

301 -1.2 MAPLE [3/4]'' [1/4]

to [3/8] 0 1 SAND 40

302 -1.2 APPLE [3/4]'' [1/4]

to [3/8] 16'' 1 SAND 40

303 -1.2 APPLE [3/4]'' [1/4]

to [3/8] 1 SAND 40

BROCCOLI

304 -1.2 APPLE [3/4]'' [1/4]

to [3/8] 1 SAND 40

BROCCOLI

305 -1.2 APPLE [3/4]'' [1/4]

to [3/8] 1 SAND 40

BROCCOLI

[0000]

No.

of

No. of ground Ground DC

AC Current

taps Material rods material Voltage

Voltage (mA)

1 Roofing 1 Copper 1.02 1.20

15

Nail

1 Roofing 2 Copper 1.02 1.20

21

Nail

1 Roofing 3 Copper 1.02 1.20

28

Nail

1 Roofing 6 Copper 1.00 1.20

45

Nail

2 Roofing 1 Copper 1.02 1.20

20

Nail

2 Roofing 2 Copper 1.00 1.20

27

Nail

2 Roofing 3 Copper 1.00 1.20

35

Nail

2 Roofing 6 Copper 1.01 1.20

57

Nail

[0000]

Conductor Conductor DC

AC Current

1 Media 2 Media Voltage

Voltage (mADC)

Copper Tree Copper Earth 0.50

0.60 10

Copper Tree Copper Tree 0.01

0.00 0.00

Roofing Tree Copper Earth 0.72

0.80 30

Nail

Roofing Tree Copper Tree 0.85

0.00 20

Nail

Roofing Tree Roofing Tree 0.02

0.00 0.00

Nail Nail

Roofing Tree Roofing Earth 0.46

0.50 1.0

Nail Nail

DC AC

Current

Conductor 1 Media Conductor 2 Media

Voltage Voltage ([mu]ADC) Elevation

Roofing Potted Copper Earth 0.60

0.20 22 Ground

Nail

Tree

level

Roofing Potted Copper Earth 0.60

0.20 21 1'' thick

Nail

Tree

pine

board

Roofing Potted Copper Earth 0.59

0.59 21 16''

Nail

Tree

wooden

box

Roofing Potted Copper Earth 0.00

0.00 0.00 Held

Nail

Tree

waist

high

[0079] The potted tree was a Norfolk Island Pine approximately

three feet tall, which was potted in a plastic pot about 40 mils.

thick.

APPENDIX B

Test 1:

DC Voltage

Time Storm distance from tree

Baseline Voltage - 1.2 V

11:00 AM About 100 miles 1.1 V

12:00 PM About 50-60 miles 1.0 V

0.5 V

1.0 V

0.5 V

2:00 PM Dissipated 1.2 V

[0080] The 12:00 PM measurements reflect fluctuations when

lightning strikes occurred.

Test 2:

DC Voltage

Time Storm distance from tree

Baseline Voltage - 1.2 V

3:00 PM 50-60 miles 1.1 V

3:15 PM 40-50 miles 1.0 V

0.3 V

1.0 V

0.3 V

3:30 PM Dissipated 1.2 V

[0081] The 3:15 PM measurements reflect fluctuations when

lightning strikes occurred.

Test 3:

DC Voltage

Time Storm distance from tree

Baseline Voltage - 1.1 V

7:45 PM 50-60 miles 1.1 V

7:55 PM 40-50 miles 0.72 V

0.85 V

0.72 V

9:16 PM Dissipated 1.1 V

[0082] The 7:55 PM measurements reflect fluctuations when

lightning strikes occurred.